Concrete Floating Floors

Floating floors systems are used for many purposes, predominantly to prevent noise passing through the floor but also to isolate against vibration and impact.

Acoustic floating floors are used to control the transmission of noise or vibration between noisy and quiet environments. Typically, acoustically isolated walls and ceilings are built on the floating floor to create a ‘box-in-box’ construction. This solution greatly reduces the noise levels or energy transmitted to the quieter area.

Acoustic Floating Floors

Concrete floating floors comprise of a reinforced concrete layer supported by isolators. The isolators can be either rubber or spring depending on the nature of the noise or vibration. There are thee main varieties of concrete floating floor:

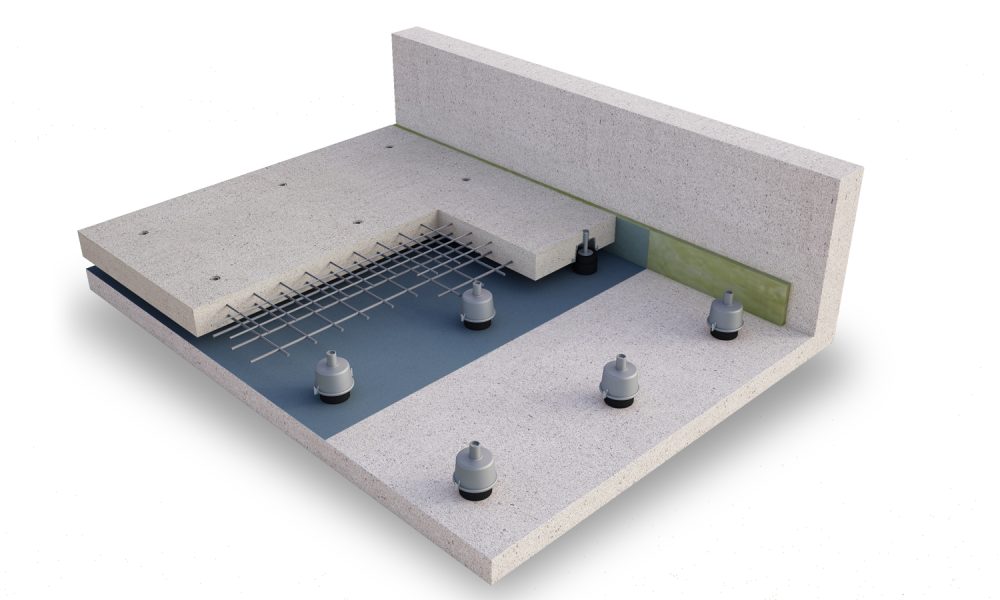

FSN Rubber concrete jack-up system

This uses the Mason jack-up system to raise a concrete layer using adjustable jacks. This system offers high levels of flexibility and guarantees an air gap. The bridge-bearing natural rubber isolators are unique to Mason. They are maintenance free, will last the life of the building and offer the best possible isolation performance of any known elastomer.

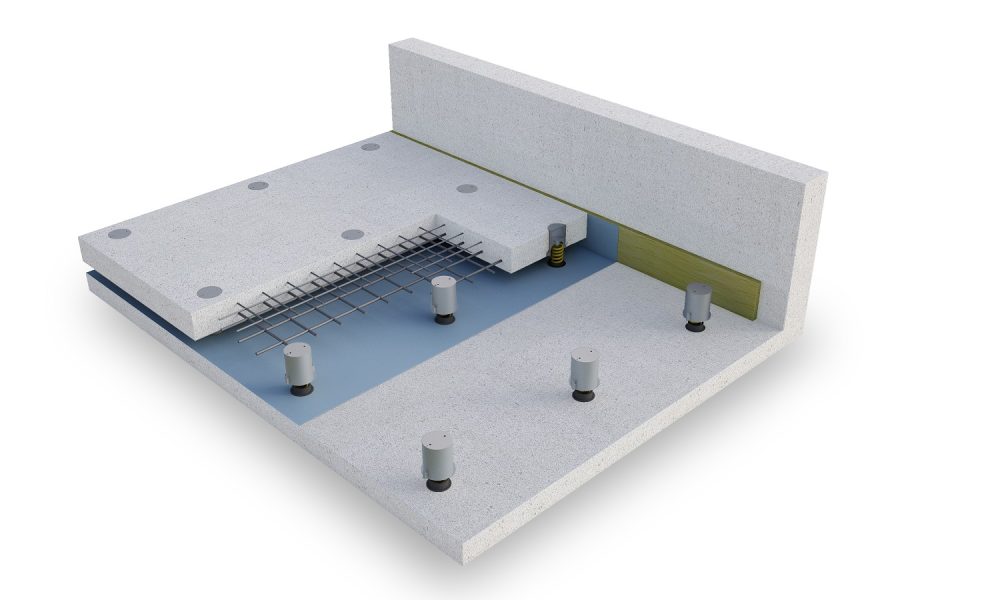

FS Spring concrete jack-up system

This is essentially the same as the FSN rubber system, but uses helical metal springs to lift and support the concrete layer. Springs are essential whenever there is very low frequency or impact noise. Springs have far less internal damping than rubber so can absorb these sources. Mason springs are shot-peened and powder-coated for excellent longevity and fatigue resistance.

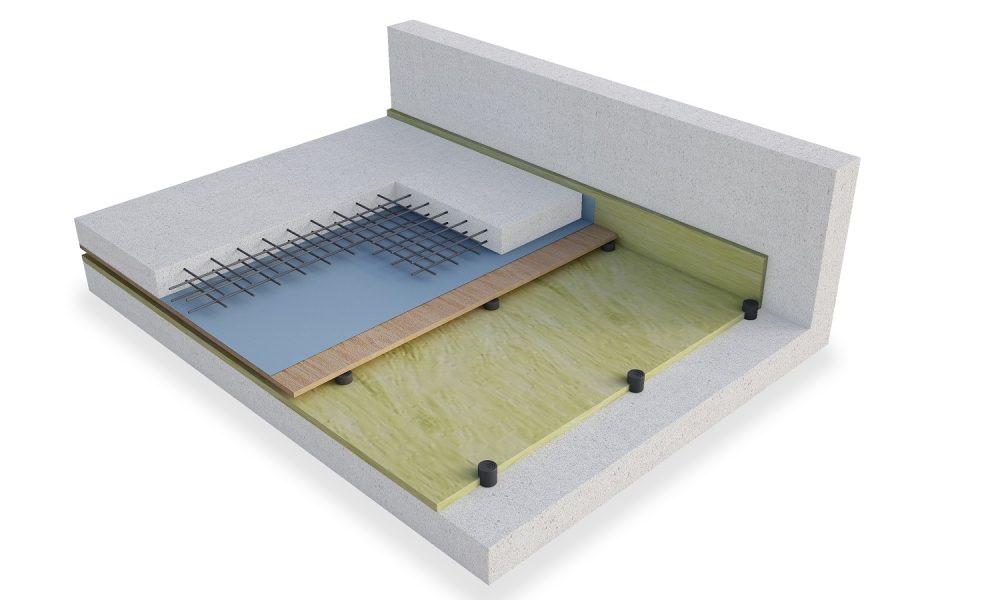

EAFM concrete formwork system

This is the traditional method of constructing a floating floor, where plywood or metal decking is placed on isolators, then a concrete layer is poured on top. Care must be taken to ensure the isolators are level and that concrete cannot pass into the air gap but excellent results can be achieved. We use the same high quality natural rubber for our formwork floors as we do for our jack-up system.

Box in Box details

Well-designed rooms incorporate the full ‘box in box’ system. This comprises of the floating floor, isolated walls and suspended ceiling. All elements are supported or suspended using isolators to ensure no solid connection between the existing structure and the space interior. We can help with any aspect of the specification or design of these elements.

If you would like to order or learn more about this product please contact Mason UK’s acoustic engineers.

| Documents & Files |

|---|

| Installation Videos |

|---|

The below video outlines in great detail the full installation of a FS coil spring concrete floating floor for a Gym.

See time-lapse installation videos below.